MANUFACTURING

Fair Work and Sustainable Production

The artificial grass industry is made up of a complex supply chain that spreads across the globe. It includes industries such as chemical suppliers, as well as fiber and backing manufacturers. These often include countries with poor fair work conditions.

We ensure the full traceability of our suppliers, and a collaboration based on trust, mutual respect, and long-term partnerships have been part of our core values since the beginnings of Realturf. Our manufacturing code of conduct, shared and approved by all of our suppliers, is based on the main conventions and documents of the United Nations and the International Labour Organization.

Since our beginnings, we have patiently reviewed and tested different developments and technologies. Today we offer you an outstanding team of experienced professionals and a quality solution on how to use the latest generation artificial grass for sports or ornamental purposes. Our products are manufactured with the sole objective of finding a balance between functionality and aesthetics.

You are invited to experience our motivation:

To make the best products!

CERTIFIED SPANISH ORIGIN

Realturf, national manufacturer of artificial grass, has been awarded with the label of the Spanish Certified Origin (OEC). The OEC seal contributes to promote and increase the economic and social value of Spanish companies that manufacture in Spain, making these companies more visible and enhancing consumer identifying of our products.

The products certified with the OEC seal went through an exhaustive audit and control of the materials to check their national origin.

OUR MANUFACTURING PROCESS

R&D and Design

Our R&D department spends every month of the year in developing the concept, design, models, and testing new products. We are in a continuous improvement process. We rely on the opinion of our thousands of clients in our design process. Our only objective is to find the balance between functionality and aesthetics.

Fiber extrusion and manufacturing

This is a key moment for the quality of our products and the proper use of the technology. The chosen raw materials are melted through an extrusion process in a perforated steel plate to create the threads that will be used later in the final product.

The threads are tightened and stretched until a fiber as fine as the natural grass remains and several fibers combine to make multiple thread spools.

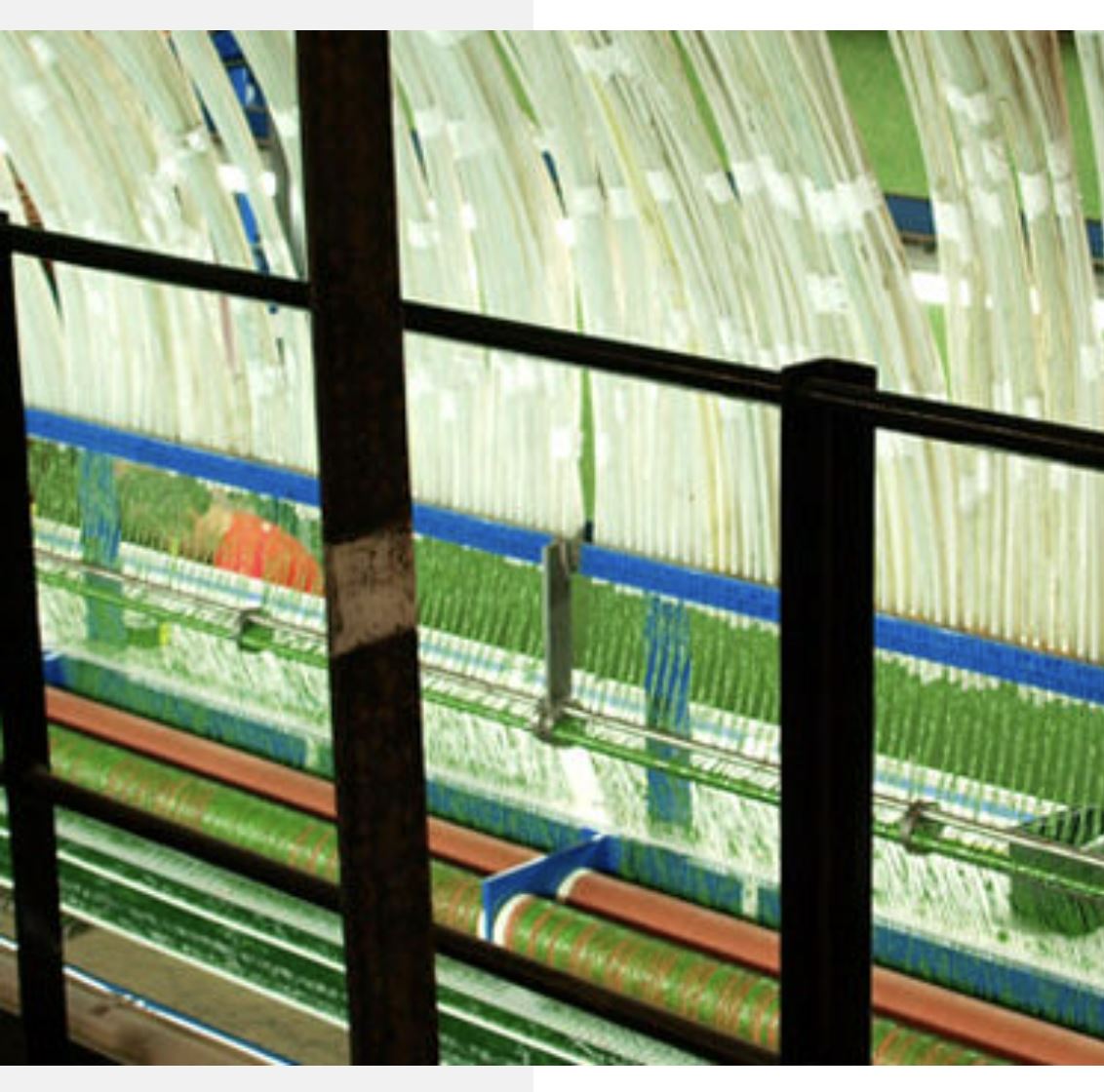

Fabric

A machine fed by hundreds of spools sews the fabric to the backing or grass base. On the other side, blades cut the fiber to the desired height, density and stitch separation which will make the manufactured product with unique final technical characteristics.

Supervision

In case there is any irregular stitch, it´s detected by a supervisor and fixed manually on the spot. According to our quality protocol, a triple supervision is carried out: while the product is woven, when going through the oven right before packaging, and when checking the technical characteristics of each batch at the lab.

Base sealing and drilling

A sealing layer is printed on the backing by a roller. An oven at constant temperature seals and gives the product dimensional stability and fiber grip. During the process high temperature needles drill the backing to help the subsequent drainage of our products.

Lab Testing

The lawn goes through internal quality controls to ensure that it complies with the technical specifications established in our ISO 9001 quality standard. Many of our products are also sent to independent laboratories to certify quality complying with regulations as strict as FIFA, RFEF, ITF, FEP, FIH, or WR.

Packaging, Labeling and Storage

The grass is finally packed in rolls of up to 70 meters (230 feet) and stored until it leaves to its destination. Each roll is labeled with a barcode that identifies every consignment produced. This barcode can trace the product until it is installed at your home or sports center. Our logistics warehouse in Alicante serves thousands of clients across all five continents.

TECHNOLOGIES REALTURF

Technologies for sensations

TRUSTED BY PROFESSIONALS

There are endless possibilities during the artificial grass design and manufacture, with a wide selection of fiber polymers or backing layer sealings. These make the final product and its performance quite different and unique. At Realturf we work to give our clients the future of artificial grass with the development of REALTECH ® Technical Artificial Grass. This technology improves the grass functionality in terms of aesthetics, durability and improves our clients´ quality of life.

In recent years, the term “technical sportswear” has become very popular. Technical sportswear refers to the clothing designed specifically for each sport. The equipment required by a person who practices mountain hiking is not the same for a person who runs in the park, even though there are similarities between both sports. A similar situation happens with artificial grass products. At Realturf we design unique collections every year with specific characteristics for each situation.

Following is a description of our main technologies specifically designed and developed to meet our clients ‘needs: